World Class Textile Producer with Impeccable Quality

World Class Textile Producer with Impeccable Quality

The main components of knitted fabrics include: cotton, viscose, polyester, acrylic, nylon, hemp, wool, silk, spandex and so on.

Cotton fiber is a kind of seed fiber made by elongating and thickening the epidermal cells of the fertilized ovule, which is different from common bast fiber. Its core component is cellulose. Cellulose is a natural polymer. The cellulose content of normal mature cotton is about 94%. In addition, it contains a small amount of polypetalous, wax, protein, fat, water-soluble substances, ash and other associated organisms. Cotton fiber has high strength, good air permeability, poor wrinkle resistance and poor tensile property. Good heat resistance, second only to hemp; Poor acid resistance, dilutes alkali resistance at room temperature; It has good affinity for dye, easy dyeing, complete chromatography and bright color. Because cotton fiber has so many excellent properties, it is also one of the most important raw materials for the textile industry.

Viscose, also known as human cotton, is a type of man-made fiber. Viscose fiber is the principal variety of man-made fiber and the second largest variety of chemical fiber in China. The principal raw material of viscose fiber is chemical pulp, including cotton pulp and wood pulp. Pure cellulose is separated and regenerated by chemical reaction. Viscose fiber has good hygroscopic property, under general atmospheric conditions. The moisture recovery rate is about 13%. After hygroscopic expansion, the diameter can be enhanced by 50%, so the viscose fabric feels hard after water, the shrinkage rate is large. The chemical composition of viscose fiber is similar to cotton, so it is more alkali resistant than acid resistant, but alkali resistance and acid resistance are worse than cotton. The dyeing property of viscose fiber is comparable to that of cotton. Viscose fiber has good hygroscopic property, easy to stain, not easy to generate static electricity, and has good spinnability, which is widely used in diverse textile, clothing and other fields.

The fabric made of viscose fiber is soft, smooth, breathable and comfortable to wear. It has bright color and good color fastness after dyeing. Suitable for making underwear, outerwear and a variety of decorative supplies.

Acrylic fiber is a synthetic fiber made of polyacrylonitrile or acrylonitrile copolymer containing more than 85% acrylonitrile. Acrylic fiber elasticity is good. Elongation 20% of the rebound rate can still maintain 65%, fluffy curl and soft. The acrylic fiber has excellent steadfastness, and its strength only decreases by 20% when it is exposed to the open air for a year. The performance of acrylic fiber is very similar to wool. The heat retention is 15% higher than wool, known as artificial wool. It has the advantages of softness, puffiness, easy dyeing, bright color, light resistance, antibacterial, not afraid of insects and so on. According to the requirements of diverse uses, it can be pure spun or blended with natural fibers. Its textiles are commonly used in clothing, decoration, industry and other fields.

Polyester fiber is a synthetic fiber produced by spinning polyester which is polycondensation of organic dibasic acid and dibasic alcohol. Invented in 1941, it is the first major variety of synthetic fiber. Polyester fiber is the biggest advantage of wrinkle resistance and conformal property is very useful, with high strength and elastic recovery ability. It is strong and durable, wrinkle-resistant, ironing free, non-stick. Polyester fiber has superior strength, high modulus and low water absorption. It widely uses as civil fabric and industrial fabric. As a textile material, polyester staple fiber can be spun purely and is especially suitable for blending with other fibers. It can be blended with natural fibers such as cotton, hemp and wool, as well as with additional chemical staple fibers such as viscose, acetate and polyacrylonitrile. The cotton-like, wool-like and flacy-like fabrics made of pure spinning or blending generally have the original excellent characteristics of polyester fiber, such as wrinkle resistance and pleating-hold, dimensional stability, wear resistance and washable wearability of the fabric, while the original shortcomings of polyester fiber, such as static electricity and dyeing difficulties in textile processing, poor perspiration absorption and air permeability, and easy melting into holes in the event of Mars, etc. It can be alleviated and improved with the mixture of hydrophilic fiber to a certain extent. Polyester twisted filament is mainly used to weave a variety of silk-like fabrics. It can also be interwoven with natural fibers or chemical staple yarn, or with silk or other chemical fibers. This interweave maintains a series of benefits of polyester.

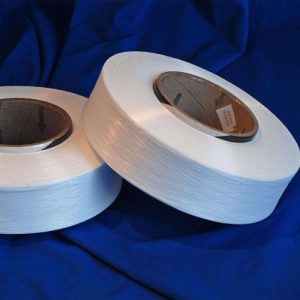

Polyester textured yarn (mainly low elastic DTY) is different from ordinary polyester filament yarn in high fluffiness, large crimp, strong hairiness, softness and high elastic elongation (up to 400%). The woven fabric has the characteristics of reliable warmth preservation, good cover and drape, soft luster and so on. It is especially suitable for weaving suit fabrics such as wool-like cloth and serge, outer garments, coats and various decorative fabrics such as curtains, tablecloth, sofa fabric and so on.

Nylon, also known as Polyamide, was developed by the outstanding American scientist Carothers and a scientific research team under his leadership. It was the first time synthetic fiber in the world. Nylon is a word for polyamide fiber (nylon). The appearance of nylon makes the textile look completely new. Its synthesis is a major breakthrough in the synthetic fiber industry, but also a very important milestone in polymer chemistry. The most prominent advantage of nylon is that the wear resistance is higher than all other fibers, the wear resistance is 10 times higher than cotton, 20 times higher than wool, slightly add some nylon fiber in the blended fabric, can greatly improve its wear resistance, when stretched to 3-6%, the elastic recovery rate can reach 100%; Can withstand tens of thousands of bending without breaking. The strength of nylon fiber is 1-2 times higher than that of cotton, 4-5 times higher than that of wool, and 3 times that of viscose fiber. However, polyamide fiber has poor heat and light resistance and poor retention, making clothes not as crisp as polyester. Nylon fiber can be blended or pure spun into a variety of knitwear. Nylon filament is used in knitting and silk industry, such as nylon stockings, nylon gauze, mosquito net, nylon lace, nylon stretch nylon outerwear, nylon silk or interwoven silk products. Nylon staple fiber is mostly used to blend with wool or other chemical fiber wool products to make a variety of wear – resistant fabrics.

Flax fiber is a fiber obtained from numerous flax plants. Flax fiber is cellulose fiber whose fabric has similar properties to cotton. Flax Fiber (including ramie and flax) can be spun pure or blended into fabrics. Linen has the characteristics of high strength, effective moisture absorption and strong thermal conductivity, especially the strength of the first natural fiber. flax fiber has the advantages that other fibers are incomparable: it has the function of good moisture absorption and ventilation, fast heat and conduction, cool and crisp, sweating is not close, light texture, strong strength, insect and mildew prevention, less static electricity, fabric is not easy to pollute, soft and generous color, rough, suitable for excretion and secretion of human skin. However, the development of flax fiber has been limited because of its insignificant elasticity, crease resistance, abrasion resistance and scratchy feeling. Nevertheless, with the development of various pre-treatment and post-processing technology, some of its natural defects have been greatly improved. Research shows that among many textile fibers, flax fiber is natural fiber with the most potential function. flax fiber has always been one of the principal textile fibers in China and enjoys a high reputation in the world.

Wool is mainly made of protein. Human use of wool can be traced back to the Neolithic Age, from Central Asia to the Mediterranean and other parts of the world spread, thus becoming the principal textile material in Asia and Europe. Wool fibers are soft and elastic, and can be utilized to make make fabrics such as wool, wool, blankets, felt and clothing. Wool products are rich to the touch, good heat preservation, comfortable to wear and so on. Wool is an essential raw material in the textile industry. It has the advantages of good elasticity, durable moisture absorption and good heat preservation. But because of the high price, it’s cotton, viscose, polyester and other fiber blended use. Wool textiles are famous for their relaxed style of elegance and comfort, and cashmere in particular has the reputation of “soft gold”.

Silk, also known as raw silk, is a kind of natural fiber. Man used one of the major animal fibers. Silk is part of the products of ancient Chinese civilization. Silk is the lightest, softest and finest organic fiber in nature. It can be easily restored to its original state after being removed from an external force. Silk fabric has excellent air permeability and moisture permeability. Silk is mainly composed of animal protein and rich in 18 kinds of essential amino acids for the human body, which can promote the vitality of skin cells and prevent hardening of blood vessels. Long-term wearing of silk fabric can prevent skin aging and has a special anti-itching effect on some skin diseases. Silk fabric has the reputation of “second skin of the human body” and “fiber queen”.

Spandex is a kind of elastic fiber, the systematic name polyurethane fiber. Spandex was successfully promoted by Bayer in Germany in 1937, and DuPont in the United States began industrial production in 1959. Spandex has excellent elasticity. The strength is 2 ~ 3 times higher than that of latex silk, the linear density is finer, and more resistant to chemical degradation. Spandex has good acid and alkaline resistance, sweat resistance, seawater resistance, dry cleaning resistance and wear resistance.

Spandex is a synthetic fiber with extraordinary breaking elongation (more than 400%), low modulus and high elastic recovery rate. Because spandex has a high degree of extensibility, it can be utilized to create high-stretch clothing. Such as: Professional sportswear, fitness suit, diving suit, swimming suit, competition swimsuit, basketball suit, bra, suspenders, ski pants, jeans, slacks, socks, leg warmers, diapers, tights, underwear, onesie, close-fitting clothing, lacing, protective clothing for surgery, protective clothing for logistics forces, short-sleeved cycling, wrestling vest, rowing suit, underwear, performance clothing, quality Clothing, etc.